Random packing is a crucial component in cooling towers, chemical reactors, and various industrial applications where efficient heat and mass transfer is required. Selecting the right random packing can dramatically improve system performance, reduce operational costs, and extend equipment lifespan. This guide provides a detailed overview of random packing types, materials, selection criteria, and applications.

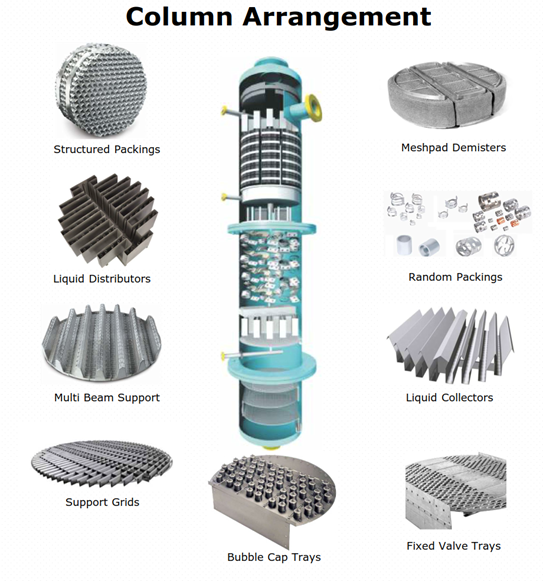

Random packing refers to loose, irregularly shaped filler materials placed inside cooling towers or reactors. Unlike structured packing, which has a fixed geometry, random packing is poured into the column to create a large surface area where liquid and gas interact. This interaction enhances heat exchange and mass transfer efficiency, making it essential for processes such as cooling, distillation, and gas absorption.

Cooling efficiency: The surface area and structure of the packing directly influence heat dissipation.

Energy consumption: Proper packing reduces air pressure drop, leading to lower fan energy usage.

Maintenance: Durable materials reduce fouling, scaling, and replacement frequency.

Process stability: Correct packing ensures uniform flow distribution and prevents channeling in towers and reactors.

Random packing comes in a variety of designs, each suited for different operational needs:

1. Pall Rings

Structure: Cylindrical rings with multiple holes in the walls, providing high surface area.

Advantages: High mass transfer efficiency with low pressure drop; suitable for high flow and temperature operations.

Applications: Absorption, distillation, and separation processes.

Structure: Simple hollow cylinders.

Advantages: Low cost, reliable performance in low-pressure applications.

Applications: Drying towers, absorption towers, cooling towers, and scrubbers.

Structure: Hollow geometric balls with multiple blades for high void fraction.

Advantages: High efficiency, low pressure drop, lightweight.

Applications: Waste gas treatment, desulfurization, wastewater treatment.

Structure: Ring-shaped with open flower-like design to maximize surface area.

Advantages: Low pressure drop, resistant to fouling, improves fluid distribution.

Applications: Cooling towers, chemical reactors, wastewater treatment.

Structure: Stepped geometric design to enhance turbulence and surface area utilization.

Advantages: High mass transfer efficiency with low pressure drop.

Applications: Distillation, absorption, and washing processes.

6. Heilex Rings

Structure: Crown-shaped design to optimize mass transfer.

Advantages: High efficiency and low pressure drop; excellent for high-performance separation.

Applications: Absorption, distillation, and industrial washing towers.

Materials of Random Packing

The choice of material is equally important and depends on the operating conditions:

Plastic (PP, PVC, HDPE, PVDF): Lightweight, corrosion-resistant, ideal for standard cooling tower applications.

Metal (Stainless steel, Carbon steel): Durable, can handle high temperatures and pressures, suitable for industrial reactors.

Ceramic: Excellent thermal stability, resistant to chemicals, used in highly corrosive environments.

Selecting the right random packing involves more than just choosing a type or material. You need to consider both general and process-specific factors to ensure optimal performance, efficiency, and durability.

General Considerations

Before choosing a random packing, consider the following:

Process requirements: Ensure the packing meets the operational conditions and performance expectations of your system.

Replacement needs: If it is replacing an existing packing, confirm compatibility with the current setup.

Familiarity: Evaluate your knowledge and past experience with the type of packing and its performance in similar applications.

Application history: Consider previous experience using a certain packing for a similar process.

Licensing requirements: Ensure the packing is suitable for licensed or regulated processes.

Process-Specific Characteristics

To select the most suitable random packing for your unique process, evaluate the following technical characteristics:

Surface Area

The surface area directly affects mass and heat transfer efficiency. A larger surface area provides more contact between liquid and vapor, enhancing performance. Typically, smaller packing sizes increase efficiency due to higher surface exposure.

Uniform Spreading Surface

Efficient liquid-vapor contact requires a uniform spreading surface. For example, while Raschig rings and Pall rings of the same size may have similar surface areas, Pall rings generally provide better liquid distribution, resulting in higher efficiency.

Uniform Distribution

Packing should allow fluids to drain freely and prevent channeling. Some older designs, like saddle-type packing, often caused liquid pockets that reduced efficiency. Modern random packing designs minimize such issues.

Wetting Rate

The wetting rate determines the stability of the packing. If the liquid film on the packing surface is interrupted, dewetting occurs, reducing efficiency. Select packings with a high and uniform wetting rate for consistent performance.

Voidage

High voidage reduces resistance to vapor flow, lowers pressure drop, and increases capacity. However, larger packing sizes increase capacity at the expense of efficiency. Choosing the right size balances efficiency and throughput.

Material

Metal: Durable, resistant to compression, high capacity and efficiency, suitable for high-pressure and high-temperature applications.

Ceramic: Excellent chemical and thermal resistance, but fragile and limited in geometry. Best for aggressive chemical or high-temperature processes.

Plastic (Polypropylene, PVC, etc.): Cost-effective and corrosion-resistant, but limited by temperature and chemical compatibility. Poor wettability can reduce efficiency; not suitable for oxidizing environments or strong solvents.

Friction

Packing with open, aerodynamic shapes minimizes friction, which enhances vapor flow and capacity.

Mechanical Strength

The packing must withstand weight and mechanical stress to ensure long-term durability without deformation or breakage.

Cooling Towers: To enhance heat dissipation in HVAC systems and industrial cooling.

Chemical Reactors: For distillation, absorption, and extraction processes.

Water & Air Treatment: Facilitates pollutant removal and efficient mass transfer.

Ensure even distribution in the tower or column to avoid channeling.

Regularly inspect for fouling and scaling, especially in hard water environments.

Match packing size to the tower or reactor diameter for optimal performance.

Consider environmental conditions such as temperature swings or corrosive agents when selecting materials.