Address

No.88, Qilian Street, High-Tech Zone, Shijiazhuang, Hebei 050000, China

Tel

+86 311 6779 0805

+86 188 4915 5666

### **Heilex Ring Packing: Overview**

**Heilex Ring Packing** is a high-efficiency random packing widely used in gas-liquid contact processes such as absorption, distillation, and scrubbing. Developed as an advanced variant of traditional Raschig rings, it combines a unique "crown-shaped" design with optimized material properties to enhance mass transfer efficiency while reducing operational costs.

### **Structural Features**

1. **Crown-Shaped Geometry**:

- The ring features a **saddle-shaped main body** with a **conical perforated cylinder** design. This structure maximizes the gas-liquid contact area by incorporating porous or corrugated surfaces, promoting turbulence and uniform distribution of phases.

- **Internal ribs** or reinforced struts improve mechanical strength and prevent deformation under high-pressure conditions.

2. **Material Diversity**:

- **Plastic**: Polypropylene (PP), reinforced PP (RPP), or chlorinated polyvinyl chloride (CPVC) for corrosion resistance in acidic/alkaline environments (e.g., H₂SO₄ scrubbing).

- **Metal**: Stainless steel or titanium for high-temperature (up to 300°C) and high-pressure applications.

- **Ceramic**: Used in extreme thermal conditions (up to 1000°C).

3. **Optimized Porosity**:

- Porosity ranges from **85% to 97%**, balancing gas-liquid flow resistance and contact efficiency. This design minimizes liquid maldistribution and gas channeling.

### **Classification**

Heilex Ring Packing is categorized based on:

1. **Material Type**:

- **PP Heilex Ring**: Most common, cost-effective, and resistant to acids/alkalis (e.g., wastewater treatment, gas scrubbing).

- **Metal Heilex Ring**: Ideal for petrochemical distillation and high-temperature reactors.

- **Ceramic Heilex Ring**: Used in sulfuric acid plants or coal gas dehydration systems.

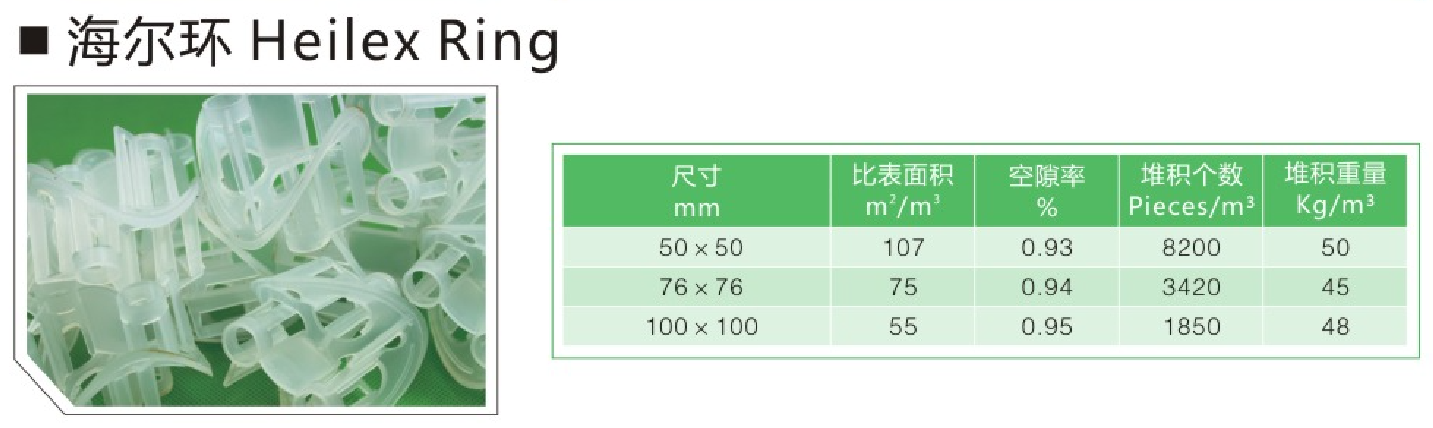

2. **Size**:

- Standard diameters: **25 mm, 50 mm, 76 mm, 100 mm**, and 145 mm. Smaller sizes enhance precision, while larger sizes suit high-capacity systems.

3. **Design Variants**:

- **Standard Hai'er Rings**: Smooth surfaces for general use.

- **Textured Hai'er Rings**: Ribbed or grooved surfaces to enhance turbulence and liquid redistribution.

### **Key Advantages**

1. **High Mass Transfer Efficiency**:

- The crown-shaped design increases surface area by **20–30%** compared to Raschig rings, achieving **3–5 theoretical plates per meter** in distillation columns.

2. **Low Pressure Drop**:

- Open structure reduces flow resistance by **15–30%**, lowering energy consumption in large-scale systems.

3. **Corrosion and Temperature Resistance**:

- PP variants withstand acids (HCl, SO₂), alkalis, and temperatures up to **120°C**; ceramic variants tolerate **1000°C**.

4. **Anti-Clogging and Self-Cleaning**:

- Smooth surfaces and optimized porosity prevent particle accumulation, reducing maintenance frequency.

5. **Mechanical Durability**:

- Resists deformation under high-pressure gas-liquid flows, ensuring long-term stability.

6. **Uniform Phase Distribution**:

- Minimizes wall flow effects and nesting between rings, ensuring even gas-liquid contact.