Address

No.88, Qilian Street, High-Tech Zone, Shijiazhuang, Hebei 050000, China

Tel

+86 311 6779 0805

+86 188 4915 5666

### **Pall Rings: Product Introduction**

**Pall Rings** are a type of high-efficiency random packing widely used in chemical, petrochemical, and environmental engineering industries. Developed as an improved version of traditional Raschig rings, Pall Rings optimize mass transfer efficiency through innovative structural design, making them a preferred choice for gas-liquid contact operations in towers and columns.

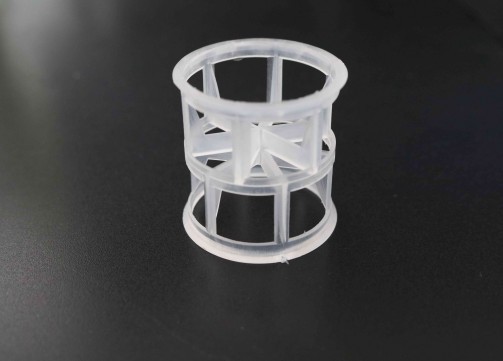

### **Structural Features**

1. **Open-Cell Design**:

- Cylindrical shape with multiple internal "windows" (perforations) and inwardly bent tabs (tongue-shaped flaps).

- Creates a high surface area-to-volume ratio for enhanced gas-liquid contact.

2. **Internal Struts**:

- Reinforced internal ribs improve mechanical strength while promoting turbulent flow.

3. **Material Variety**:

- Available in metals (stainless steel, aluminum), plastics (PP, PVC, PVDF), and ceramics to suit different operating conditions.

### **Classification**

Pall Rings are categorized based on:

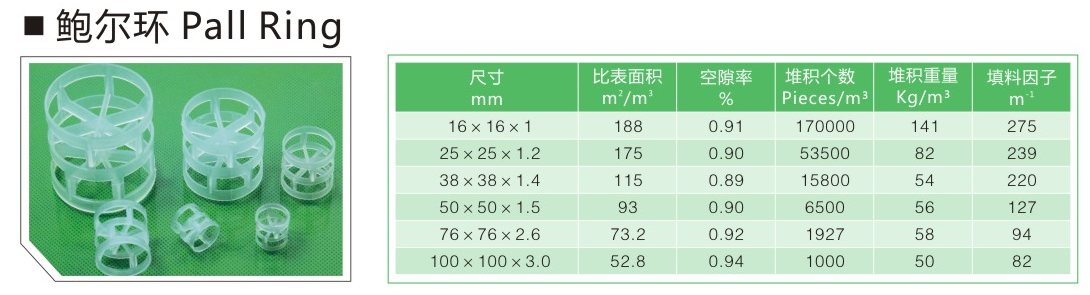

1. **Size**:

- Standard sizes range from 15 mm to 100 mm in diameter.

- Smaller sizes (e.g., 16 mm, 25 mm) for high-precision applications; larger sizes for high-capacity systems.

2. **Material Type**:

- **Metal Pall Rings**: Ideal for high-temperature, high-pressure, or corrosive environments.

- **Plastic Pall Rings**: Lightweight, cost-effective, and resistant to acids/alkalis.

- **Ceramic Pall Rings**: Used in extreme thermal or corrosive conditions.

3. **Design Variants**:

- **Standard Pall Rings**: Basic design for general-purpose applications.

- **Super Pall Rings**: Enhanced geometry for lower pressure drop and higher efficiency.

### **Key Advantages**

1. **High Mass Transfer Efficiency**:

- Internal tabs and perforations create turbulent flow, improving mixing and phase contact.

2. **Low Pressure Drop**:

- Open structure reduces resistance to gas/liquid flow, saving energy.

3. **High Void Volume**:

- Up to 90–95% void ratio minimizes flooding risk and increases throughput.

4. **Operational Flexibility**:

- Performs well across a wide range of flow rates and liquid-to-gas ratios.

5. **Durability**:

- Robust construction resists thermal deformation and chemical corrosion.

### **Applications**

Pall Rings are widely used in:

1. **Distillation Columns**:

- Separation of hydrocarbon mixtures, ethanol purification, etc.

2. **Absorption Towers**:

- Gas scrubbing (e.g., CO₂ removal, HCl absorption).

3. **Stripping Columns**:

- Volatile organic compound (VOC) recovery.

4. **Cooling Towers**:

- Heat and mass transfer enhancement.

5. **Environmental Systems**:

- Waste gas treatment, desulfurization, and wastewater aeration.

### **Comparison with Other Packing**

- **Vs. Raschig Rings**: Pall Rings offer 30–50% higher efficiency and 50–70% lower pressure drop.

- **Vs. Structured Packing**: Lower cost and easier installation, though slightly less efficient in some high-purity applications.

### **Conclusion**

Pall Rings revolutionized random packing technology by balancing efficiency, capacity, and energy savings. Their adaptability to diverse industrial processes and materials ensures long-term relevance in separation and reaction engineering.