Address

No.88, Qilian Street, High-Tech Zone, Shijiazhuang, Hebei 050000, China

Tel

+86 311 6779 0805

+86 188 4915 5666

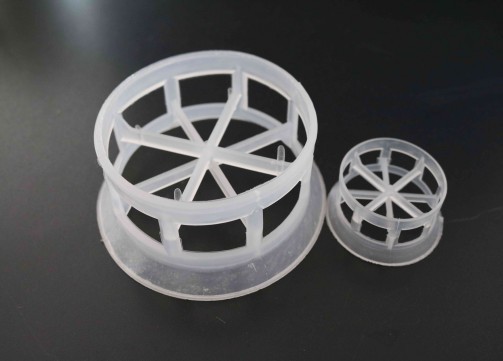

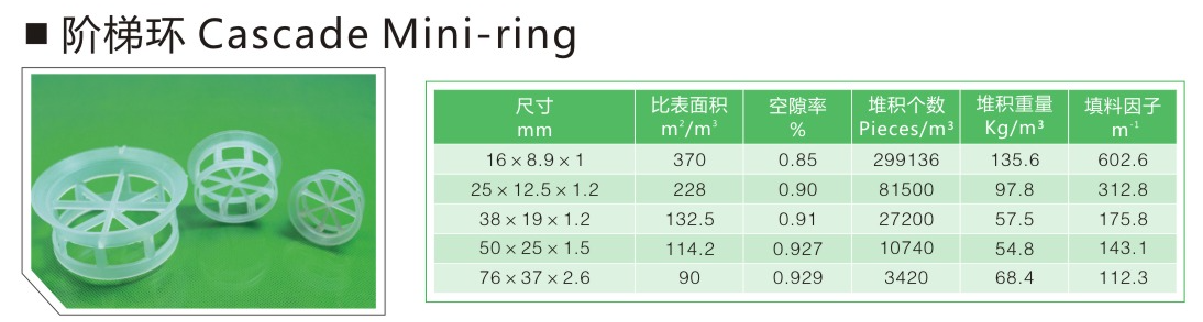

### **Cascade Mini-ring: Overview**

**Cascade Mini-ringg** is a high-performance random packing designed to optimize gas-liquid contact in industrial separation processes such as distillation, absorption, and scrubbing. Its unique stepped geometry enhances turbulence and surface area utilization, making it a popular choice for applications requiring high efficiency and low energy consumption.

### **Structural Features**

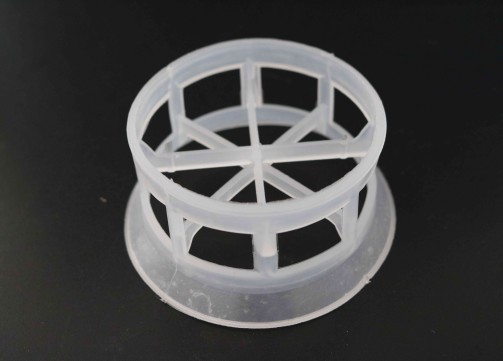

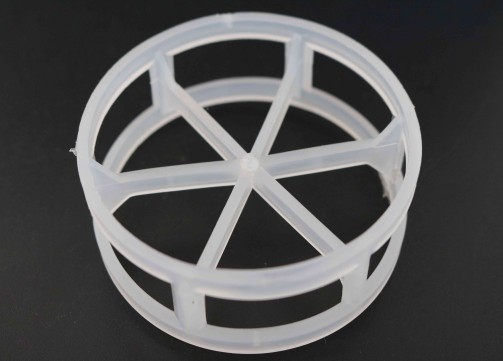

1. **Stepped Cylindrical Design**:

- Cylindrical shape with **internal or external step-like ridges** that disrupt laminar flow and create micro-turbulence.

- Perforations or "windows" on the surface improve fluid redistribution and minimize dead zones.

2. **Material Options**:

- **Plastic**: Polypropylene (PP), PVC, or PVDF for corrosion resistance and lightweight applications.

- **Metal**: Stainless steel, titanium, or aluminum for high-temperature, high-pressure systems.

- **Ceramic**: Used in extreme thermal (up to 1000°C) or corrosive environments.

3. **Reinforced Geometry**:

- Internal ribs or crossbars enhance mechanical strength while maintaining a high void volume (up to **95–98%**).

### **Classification**

1. **By Material**:

- **Plastic Cascade Mini-ring**: Cost-effective for acid/alkali scrubbing (e.g., PP in wastewater treatment).

- **Metal Cascade Mini-ring**: Ideal for petrochemical distillation or reactive gas absorption.

- **Ceramic Cascade Mini-rings**: Used in sulfuric acid production or high-temperature gas drying.

2. **By Size**:

- Diameters range from **15 mm to 100 mm**; smaller sizes for precision processes, larger for high-throughput systems.

3. **By Surface Design**:

- **Smooth Surface**: Standard for general-purpose use.

- **Textured/Ribbed Surface**: Enhanced liquid film distribution and turbulence.

### **Key Advantages**

1. **Superior Mass Transfer Efficiency**:

- Stepped ridges and perforations increase surface area by **20–30%** compared to traditional Raschig rings, improving phase contact.

2. **Low Pressure Drop**:

- Open structure reduces flow resistance, lowering energy costs by **15–25%** versus conventional packing.

3. **High Mechanical Stability**:

- Reinforced design prevents deformation under heavy loads or thermal stress.

4. **Corrosion and Temperature Resistance**:

- Compatible with aggressive chemicals (e.g., HCl, SO₂) and temperatures ranging from **-50°C to 300°C** (plastic/metal) or **1000°C** (ceramic).

5. **Anti-Clogging Performance**:

- Self-cleaning geometry minimizes fouling in systems with particulate-laden fluids.