As industrialization progresses, wastewater treatment has become an essential part of environmental protection and resource recycling. Among various wastewater treatment technologies, MBBR (Moving Bed Biofilm Reactor) stands out for its efficiency, compact footprint, and energy savings. It is widely applied in municipal wastewater, industrial effluent, and aquaculture systems. Long Zhuo provides high-quality MBBR media to ensure optimal performance for these applications.

MBBR technology is a type of biofilm-based wastewater treatment method. It uses high surface area plastic carriers—known as MBBR media—placed in aeration tanks to provide surfaces for biofilm attachment. Microorganisms growing on these surfaces degrade organic pollutants in the water. This approach combines the advantages of activated sludge and fixed-film systems, offering high treatment capacity, stable operation, and smaller space requirements.

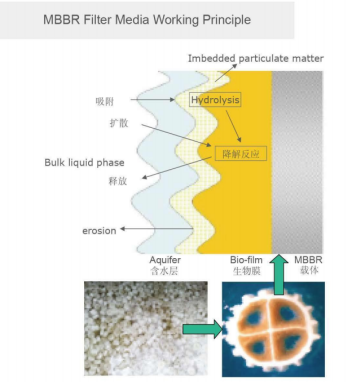

The operation of an MBBR system is based on the principle of biofilm growth on moving carriers:

Media Movement: The MBBR media floats and moves freely in the aeration tank, increasing contact between wastewater and biofilm.

Biofilm Development: Microorganisms attach to the media’s surface, forming a stable biofilm layer that digests organic pollutants.

Wastewater Treatment: Contaminated water flows through the tank, allowing microbes to break down organic matter, ammonia, and other pollutants.

Self-Cleaning Effect: The movement of the media prevents biofilm overgrowth and sludge accumulation, maintaining stable treatment efficiency.

By using this approach, MBBR systems achieve high treatment efficiency, low sludge production, and minimal maintenance requirements.

Tank Geometry: Proper tank shape and depth optimize media circulation and prevent dead zones.

Aeration System: Adequate air supply maintains oxygen levels and drives media movement.

Media Selection: Long Zhuo MBBR media are engineered with high surface area, uniform density, and optimized shapes for enhanced biofilm attachment.

Retention Time: The hydraulic retention time is carefully calculated to maximize pollutant removal efficiency.

High Surface Area: Media surfaces provide extensive attachment space for microbes, increasing biodegradation capacity.

Hydrodynamic Flow: The media move freely in the tank, ensuring uniform water distribution and preventing channeling.

Enhanced Oxygen Transfer: The design facilitates oxygen transfer from aeration, supporting aerobic microbial activity.

Durability: High-quality HDPE or PP materials resist wear, chemical corrosion, and mechanical stress, ensuring long-term stability.

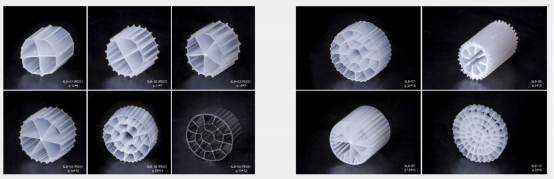

Bio Ball Media: Spherical shape, high surface area, ideal for municipal and industrial wastewater.

Bio Ring Media: Ring shape enhances oxygen transfer and supports high-load treatment.

Bio Cube Media: Cube shape ensures maximum surface area and durability for intensive systems.

Using Long Zhuo MBBR media provides numerous advantages for wastewater treatment systems, making it ideal for municipal, industrial, and aquaculture applications:

High Treatment Efficiency: Long Zhuo media offer a large surface area for microbial attachment, promoting strong biofilm growth. This effectively enhances the removal of organic pollutants, ammonia, and nitrogen compounds, improving overall wastewater treatment performance.

Stable and Consistent Operation: The optimized design ensures uniform media distribution and steady water flow within the reactor. This prevents dead zones, channeling, and biofilm overgrowth, maintaining reliable performance even under variable load conditions.

Reduced Sludge Production: The biofilm-based process generates less excess sludge compared to conventional systems, reducing sludge handling and disposal requirements and lowering operational costs.

Compact and Space-Saving: MBBR systems using Long Zhuo media require smaller tank volumes while achieving high treatment capacity, saving valuable space in plant layouts.

Durability and Chemical Resistance: Made from high-quality HDPE or PP, Long Zhuo media resist chemical corrosion, wear, and mechanical stress, ensuring long-term durability and minimizing replacement frequency.

Enhanced Oxygen Transfer: The carefully engineered media shapes improve water circulation and oxygen distribution, supporting aerobic microbial activity and accelerating pollutant degradation.

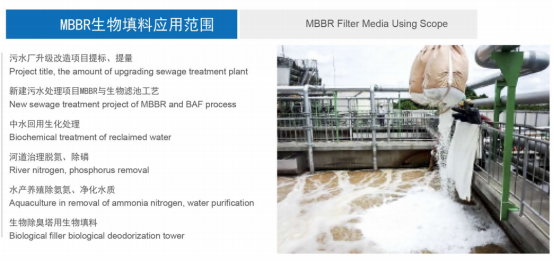

Versatile Application: Long Zhuo MBBR media are suitable for diverse wastewater types, from municipal sewage to industrial effluent and aquaculture water, providing tailored solutions for different treatment needs.

Low Maintenance and Operational Cost: The media’s self-cleaning movement reduces the risk of clogging and biofilm overgrowth, minimizing maintenance efforts and operational interruptions.

Environmentally Responsible Solution: By improving treatment efficiency and reducing sludge generation, Long Zhuo media help lower environmental impact and support sustainable water management practices.

Choosing the right MBBR media is essential for achieving high efficiency, stable operation, and long-term reliability in wastewater treatment. Long Zhuo provides advanced MBBR media designed for optimized biofilm growth, hydrodynamics, and oxygen transfer, making it the preferred choice for municipal, industrial, and aquaculture applications.