Tube settlers (also called lamella clarifiers) are an efficient technology for sedimentation and solids removal in wastewater treatment. By increasing the effective settling surface area inside a tank, they allow smaller tank sizes, faster processing, and better removal of fine suspended solids, compared with conventional sedimentation methods.

A tube settler consists of inclined tubes or lamella plates installed inside a sedimentation tank. Wastewater flows upward through these tubes, and suspended solids settle onto the tube surfaces. Settled solids slide down into the sludge collection area at the bottom.

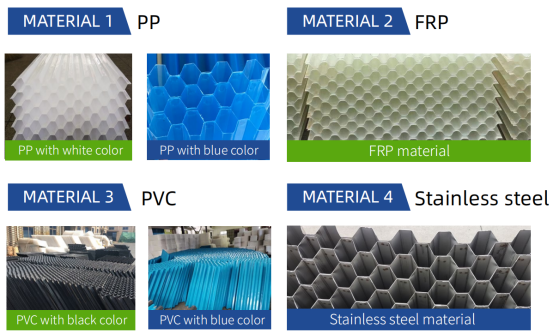

Construction materials:

PVC / Polypropylene (PP): Lightweight, corrosion-resistant, suitable for normal wastewater.

Fiberglass-Reinforced Plastic (FRP): Strong and chemically resistant, suitable for industrial applications.

Stainless Steel (SS): Ideal for high-temperature or highly corrosive wastewater.

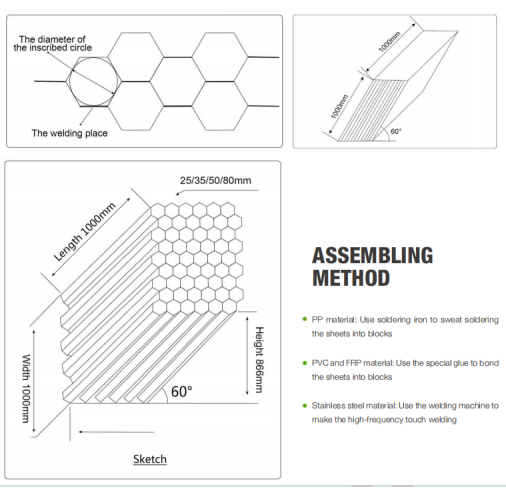

Inclination: Typically 45°–60°, allowing solids to slide downward naturally.

Modular design: Can be retrofitted into existing tanks or scaled for larger capacities.

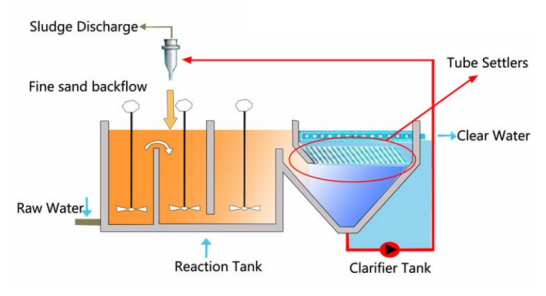

Wastewater enters the inlet zone and distributes evenly across the tube sections.

Water moves upward through inclined tubes, where solids settle on surfaces.

Settled solids slide down to the sludge hopper.

Clarified water exits from the top for further treatment.

Key point: Tube settlers reduce the hydraulic retention time required for sedimentation while improving the removal of fine particles, achieving better effluent quality without increasing tank size.

Parameter | Typical Range / Recommendation |

Tube length | 1–3 m |

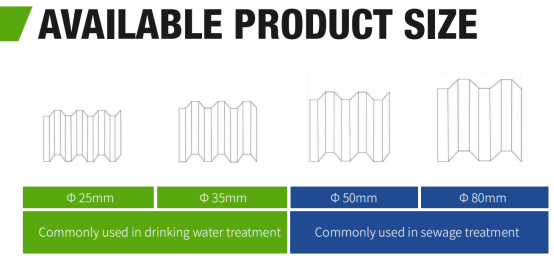

Tube diameter | 50–100 mm, depending on particle size and flow rate |

Tube spacing | 25–50 mm |

Inclination angle | 45°–60° |

Hydraulic loading rate | 0.8–2.0 m³/m²·h |

Material selection | PVC/FRP for normal water; SS for corrosive or high-temperature water |

Sludge hopper slope | 45°–60° to allow smooth solids discharge |

Note: Parameters can be customized based on wastewater characteristics and treatment plant requirements.

Tube settlers are widely used in industries and facilities requiring efficient sedimentation in limited space:

1. Municipal Wastewater Treatment

Enhances primary and secondary clarification.

Reduces load on downstream filtration and disinfection systems.

Especially useful in urban areas with limited land availability.

2. Industrial Wastewater Treatment

Applied in textile, chemical, food, beverage, and pharmaceutical industries.

Prevents clogging in pumps, filters, and downstream equipment.

3. Cooling Towers & Process Water Systems

Removes suspended solids from make-up water.

Protects heat exchangers, pumps, and cooling towers.

4. Stormwater Treatment

Settles sediment and debris from runoff before discharge to rivers or ponds.

5. Retrofit and Upgrade Projects

Tube settlers can be added to existing sedimentation tanks to increase capacity and efficiency without new construction.

Advantage | Explanation |

Smaller Footprint | Inclined tubes provide larger effective settling area, reducing tank volume by 50–70%. |

Higher Solids Removal Efficiency | Captures fine suspended particles (down to 20–50 microns) that traditional tanks may leave in suspension. |

Faster Sedimentation | Shorter hydraulic retention time allows higher throughput. |

Lower Sludge Handling Requirements | Settled solids slide down in concentrated form, simplifying removal. |

Gravity-Driven Operation | No pumps or mechanical parts needed, reducing energy use and maintenance. |

Modular and Flexible | Can be scaled or retrofitted, adapting to varying flow rates. |

Improved Water Clarity | Produces higher-quality effluent, reducing the burden on downstream treatment. |

Summary: Tube settlers allow plants to increase capacity, improve water clarity, and reduce construction and operational costs, while handling fine suspended solids efficiently.

Tube settlers offer a compact, reliable, and low-maintenance solution for sedimentation in wastewater and industrial water treatment. By increasing effective settling surface area, they enable higher flow capacities, better water clarity, and reduced tank sizes. Their modular design, low energy requirements, and high efficiency make them suitable for municipal, industrial, and cooling tower applications.