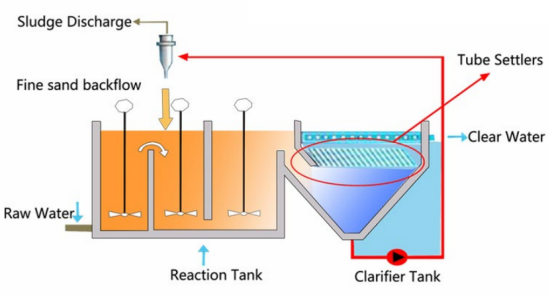

In modern water and wastewater treatment, efficient solid‑liquid separation is essential for meeting regulatory quality standards and reducing downstream filtration costs. Traditional sedimentation basins rely on gravity to remove suspended solids, but they require expansive tank footprints and long detention times. This is where tube settlers—also referred to as plate settlers or lamella clarifiers—offer a powerful solution. By increasing the effective settling surface area within a compact space, these technologies dramatically accelerate particle removal and improve treatment efficiency.

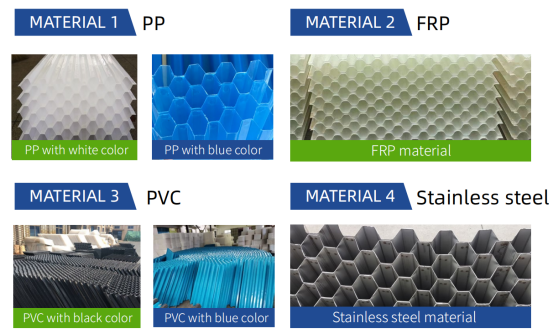

A tube settler is a passive gravity sedimentation device composed of multiple inclined tubular channels or packs installed inside a clarifier or sedimentation basin. The tubes are usually made from polypropylene (PP) or PVC and are arranged at an optimal incline—commonly around 60 degrees—to maximize settling performance.

As water flows upward through these inclined tubes, suspended particles—especially flocculated solids—settle out of the water stream and adhere to the inner surface of the tubes. The key principles at work are:

Large Effective Settling Area: By stacking many inclined tubes close together, the total settling surface becomes much larger compared to a plain, open clarifier basin. This allows particles to encounter surfaces more quickly and reduces the distance they need to fall under gravity, accelerating their removal.

Shortened Settling Path: The incline reduces the vertical settling distance required for particles to fall onto a surface. This results in much faster sedimentation than in conventional clarifiers, where particles must sink all the way to the bottom.

Mass Accumulation and Sludge Flow: As particles accumulate on the tube surfaces, they form compact masses. Gravity causes these masses to slide down the tubes into a concentrated sludge zone at the bottom of the tank, making sludge removal easier.

Tube settlers successfully capture fine floc that escapes the main clarification zone, converting small, slow‑settling particles into larger, more settleable aggregates.

A lamella clarifier, often used interchangeably with the term “plate settler,” is a sedimentation system where flat, inclined plates replace tubular channels. These plates are mounted in parallel and spaced a short distance apart to create many shallow settling zones.

The lamella clarifier’s operational principle is very similar to a tube settler:

Influent water with suspended solids enters the clarifier and flows upward between the inclined plates.

Particles settle onto the plates due to gravity, sliding down the plates into a sludge hopper at the bottom.

Clarified water rises between the plates and exits over weirs at the top.

Because the plates are inclined (typically between 45° and 60°), they maintain an efficient counter‑current flow where water moves up while solids descend. This arrangement greatly increases the surface area available for sedimentation within a minimal tank footprint.

Though both technologies are based on the same shallow‑depth sedimentation principle, there are important differences:

1. Geometry and Material

Tube Settlers: Typically consist of circular or hexagonal tubes made from plastic materials like PP or PVC. They are lightweight, modular, and easy to install or retrofit.

Plate Settlers: Use flat plates (often stainless steel or coated materials) mounted on angled frames. These units can offer longer service life and higher resistance to abrasion.

2. Surface Area and Performance

Both systems increase the effective settling area relative to conventional clarifiers, but plate settlers generally provide a slightly higher projected surface area due to flat plate geometry.

3. Footprint and Flow Capacity

Lamella plate systems may handle somewhat higher flow rates and achieve the same performance in a smaller footprint compared to some tube designs, making them suitable for larger installations.

4. Maintenance and Cleaning

Tube settlers’ narrow channels may be more prone to clogging if turbid loads are high, requiring regular inspection. Plate settlers usually allow easier access between plates for cleaning.

Tube settlers and lamella clarifiers are effective under a wide range of applications including:

Drinking water production: Enhancing sedimentation after coagulation and flocculation.

Municipal wastewater treatment: Reducing loads on downstream biological processes.

Industrial effluent treatment: Managing solids in process water or cooling systems.

By multiplying the settling area and reducing detention time, these systems improve overall plant performance, reduce tank size and footprint, and lower capital and operational costs.