When it comes to coastal and marine construction, choosing the right materials for seawalls, bulkheads, and other water-related structures is crucial. One material that has gained significant traction in these industries is PVC (Polyvinyl Chloride) sheet piling. Long Zhuo, a leading manufacturer of high-quality vinyl seawall panels, vinyl sheet piling, and PVC sheet piles, has established a strong reputation for producing durable and reliable solutions for marine construction projects.

PVC sheet piles, including U-type, Z-type, and W-type configurations, offer unparalleled strength, ease of installation, and resistance to corrosive saltwater environments. In this article, we'll explore the different types of PVC sheet piling, their unique characteristics, applications, and why they are becoming a preferred material in modern construction.

PVC sheet piling refers to interlocking panels made from Polyvinyl Chloride (PVC) used for the construction of barriers, retaining walls, and marine structures. The unique design of PVC sheet piles allows them to interlock tightly, creating an impermeable barrier that resists water and environmental damage.

There are three main types of PVC sheet piles:

| Product Name | Type / Structure | Strength Grade | Corrosion Resistance | Application Scenarios | Service Life | Connection Type | Customizable |

|---|---|---|---|---|---|---|---|

| U-Type Vinyl Seawall Panels | U-shaped profile | High | ⭐⭐⭐⭐⭐ | Marine seawalls, canals, lakefronts, golf course shores | 50+ years | Interlocking U-Panel | ✅ Yes |

| Vinyl Sheet Piling | Flat or Z-type | Medium to High | ⭐⭐⭐⭐ | Flood control, riverbanks, infrastructure | 40–50 years | Interlock tongue & groove | ✅ Yes |

| Seawalls Bulkheads Retaining Walls PVC Sheet Piles | Composite options (U/Z) | High | ⭐⭐⭐⭐⭐ | Retaining walls, bulkheads, ports, marine construction | 50+ years | Tongue & groove or custom lock | ✅ Yes |

Each type has its own specific applications and benefits, making PVC an adaptable choice for a range of marine and civil engineering projects.

One of the standout features of PVC sheet piles is their exceptional resistance to corrosion. Unlike steel or wood, which can degrade when exposed to saltwater, PVC is inherently resistant to saltwater corrosion, making it ideal for use in marine environments. PVC sheet piling is also unaffected by chemical exposure, ensuring longevity and a minimal need for maintenance.

PVC sheet piles are significantly lighter than traditional steel or concrete alternatives, making them easier to transport and install. The lightweight nature reduces labor and equipment costs, allowing for faster project completion.

PVC is known for its durability. PVC sheet piling can withstand harsh environmental conditions for decades without degrading. Long Zhuo’s products, such as vinyl seawall panels, are designed to provide a long-lasting solution for coastal and marine projects, often lasting more than 50 years with minimal maintenance.

As a sustainable building material, PVC sheet piling is recyclable, contributing to a greener environment. Moreover, the production of PVC sheet piles consumes less energy compared to steel or concrete alternatives, making it a more eco-friendly choice for large-scale projects.

PVC sheet piles can be easily customized to meet the specific needs of a project. Whether it’s a seawall, bulkhead, or cofferdam, PVC sheet piling can be tailored in size, shape, and color to fit the project’s aesthetic and functional requirements.

The U-type vinyl seawall panels offered by Long Zhuo are designed for seawall and bulkhead applications. These panels are particularly beneficial for coastal erosion protection, providing a solid barrier that prevents water from seeping through. Their unique U-shape design ensures maximum stability and strength, offering excellent resistance to the corrosive effects of saltwater. U-type vinyl seawalls are ideal for use in high-energy environments like harbors, marinas, and riverbanks.

Applications: Seawalls, bulkheads, coastal erosion control

Z-type vinyl sheet piling is an ideal choice for retaining walls and erosion control structures. This type of sheet pile offers exceptional interlocking capabilities, allowing for secure and efficient installation. Z-type sheet piling can be easily driven into the soil, making it a practical option for projects that require robust erosion protection and stabilization. The Z-type design ensures a tight interlock, providing long-lasting protection against soil movement and water infiltration.

Applications: Retaining walls, flood prevention, erosion control

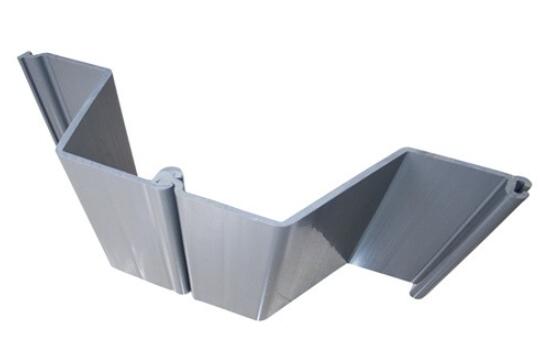

W-type PVC sheet piles are best suited for cofferdams and cut-off wall applications. These panels offer superior strength, ensuring that they can withstand the pressure of water and soil while maintaining a solid and impermeable barrier. The W-type design is ideal for large-scale civil engineering projects, such as construction sites that need to be dewatered or waterlogged areas that need to be isolated.

Applications: Cofferdams, cut-off walls, underground construction projects

One of the key advantages of PVC sheet piles is their ease of installation. Due to their lightweight nature, these piles can be easily driven into the ground using minimal equipment. Long Zhuo’s U-type, Z-type, and W-type sheet piles are designed for easy interlocking, reducing the need for complex assembly and ensuring a seamless fit.

The installation process involves driving the PVC sheet piles into the ground with specialized equipment, such as vibratory or impact hammers. Once in place, the interlocking panels form a tight, continuous barrier.

The lightweight nature of PVC sheet piles also means reduced transportation and handling costs. Since they are easy to install and require less labor, the overall cost of a marine construction project can be significantly reduced.

While steel and concrete have traditionally been used in marine and coastal construction, PVC sheet piles offer several key advantages over these materials. Steel is prone to rust and corrosion in salty environments, which can lead to significant maintenance costs. Concrete, on the other hand, is heavy, difficult to transport, and prone to cracking under extreme conditions.

PVC sheet piles, on the other hand, are corrosion-resistant, lightweight, and cost-effective. They provide long-lasting performance in harsh marine environments and require little maintenance, making them an excellent alternative to traditional materials.

PVC sheet piles require minimal maintenance compared to traditional materials like steel or wood. With no need for regular painting or repairs, they offer significant cost savings over the long term.

The demand for PVC sheet piles is expected to continue growing as more industries and governments turn toward environmentally friendly and cost-effective solutions for marine and coastal construction. According to industry reports, the global market for sheet piling is projected to grow at a CAGR of 5.1% over the next five years.

In addition, advancements in PVC technology are driving innovation in the sheet piling industry. Enhanced materials, such as fiberglass-reinforced PVC, are making the product even stronger and more resistant to wear and tear, expanding the possibilities for applications in extreme environments.

As a sustainable, durable, and cost-effective alternative to traditional materials, PVC sheet piles, including Long Zhuo’s U-type, Z-type, and W-type designs, are transforming the landscape of marine and coastal construction. Their ease of installation, low maintenance costs, and resistance to harsh environmental conditions make them the ideal solution for a variety of applications, from seawalls to retaining walls and cofferdams.

With an increasing focus on environmental sustainability and long-term cost efficiency, PVC sheet piles are set to play a crucial role in shaping the future of marine infrastructure projects.

Q1: How long do PVC sheet piles last?

PVC sheet piles can last over 50 years with minimal maintenance, making them a long-term investment for coastal and marine construction.

Q2: Are PVC sheet piles environmentally friendly?

Yes, PVC sheet piles are recyclable and require less energy to produce compared to steel or concrete alternatives, making them a more sustainable choice.

Q3: What is the cost difference between PVC and steel sheet piling?

PVC sheet piles are generally more cost-effective than steel, due to lower material and maintenance costs over the lifespan of the structure.