Rising sea levels, stronger storms, and increasing rainfall have made flood control and erosion prevention critical for coastal, riverside, and low-lying areas. Traditional methods using timber, steel, or concrete often face corrosion, high maintenance, or structural failure. PVC sheet piles provide a durable, cost-effective, and environmentally safe alternative.

PVC sheet piles are high-strength interlocking panels made of polyvinyl chloride (PVC). They form continuous walls capable of resisting water pressure, soil lateral pressure, and erosion forces.

Key Material Properties and Performance Indicators:

Density: 1.4–1.5 g/cm³

Tensile Strength: 45–55 MPa

Flexural Strength: 70–90 MPa

Temperature Resistance: -40°C to +60°C

UV Stabilization: ASTM G154 Level 3, suitable for prolonged sunlight exposure

Corrosion Resistance: Resistant to saltwater, freshwater, acidic and alkaline soils

Service Life: Over 30 years in marine environments

Weight: Approximately 40 times lighter than steel, facilitating transport and installation

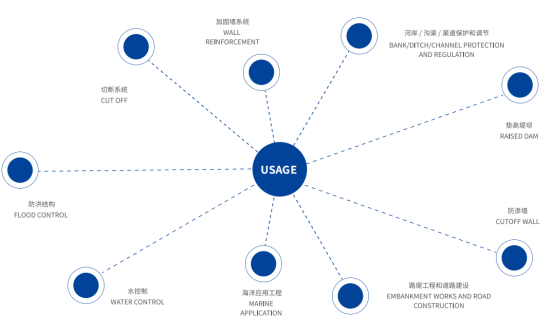

PVC sheet piles can be installed in coastal and riverside areas to manage water overflow and prevent property damage.

1. Seawalls and Bulkheads

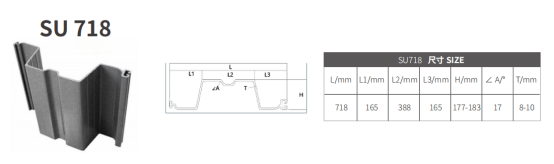

Profile: W-Type interlocking PVC sheet pile

Width: 718 mm, Depth: 180 mm, Thickness: 12–16 mm

Water Pressure Resistance: Up to 8 kPa per meter height

Installation Depth: 2–6 m depending on soil and water conditions

Creates a continuous barrier blocking tidal surges and floods with minimal seepage.

2. Cutoff Walls for Flood Zones

Profile: U-Type for high water retention

Depth: 1–4 m for temporary barriers, up to 6 m for permanent walls

Advantages: Rapid installation, reusable in emergency scenarios

Design Considerations:

Match pile depth to expected flood levels with a 1.2–1.5 safety factor

Consider soil type (sand, clay, silt) for driving method and stability

Integrate with drainage or pumping systems to manage overflow

PVC sheet piles protect soil from water and wind erosion, stabilizing slopes and shorelines.

1. Retaining Walls

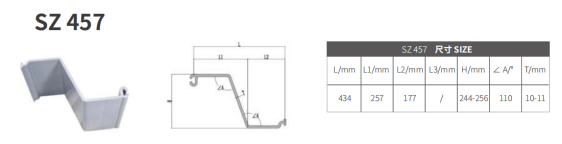

Profile: Z-Type, flexible and strong for slope retention

Height: 1–5 m

Lateral Soil Pressure Resistance: Up to 20 kPa

Backfill Material: Sand, gravel, or soil for additional stability

2. Shoreline Stabilization

Designed to absorb wave energy without deformation

UV stabilized PVC maintains structural integrity under sunlight

Low maintenance: No repainting or corrosion protection required

Integration and Combination:

Can be combined with concrete capping, sandbags, or vegetated slopes

Can integrate with riprap or geotextiles for enhanced erosion protection

1. Planning and Design

Determine wall type: seawall, retaining wall, bulkhead, or cutoff wall

Analyze soil conditions, water depth, wave or flood pressure, and environmental factors

2. Selection of Profiles

W-type: High-strength seawalls and bulkheads

Z-type: Flexible retaining walls

U-type: Cutoff walls or cofferdams for maximum water resistance

3. Installation

Use a pile driver, hydraulic hammer, or vibration hammer to drive piles

Interlock panels to form a continuous wall

Backfill with soil, sand, or gravel for additional stability

4. Maintenance

Inspect joints and panels periodically

Remove debris or sediment buildup to ensure long-term performance

Minimal maintenance compared to steel or timber, no corrosion concerns

Installation Reference Data:

Typical installation speed: 5–8 meters per hour per pile driver

Anchoring recommended for walls over 4 m high or in high-wave areas

Pre-drilling may be required in dense soil or rocky terrain