Galvanized steel water tanks are constructed using hot-dip galvanizing, forming a dense zinc protective layer on the steel surface. This layer isolates the steel from corrosive elements such as moisture and oxygen. Even in harsh coastal environments with high salt and humidity, the zinc coating acts as a “sacrificial anode,” providing active corrosion protection and extending the tank’s service life by 3–5 years compared to conventional water tanks.

1. Corrosion Resistance and Extended Lifespan

Dense zinc coating formed via hot-dip galvanizing protects steel from moisture and oxygen.

Sacrificial anode mechanism ensures the steel substrate remains intact even if the coating is scratched.

Durability in extreme conditions: Maintains structural integrity in coastal, high-humidity, and industrial environments.

Typical service life can exceed 50 years with proper installation and maintenance.

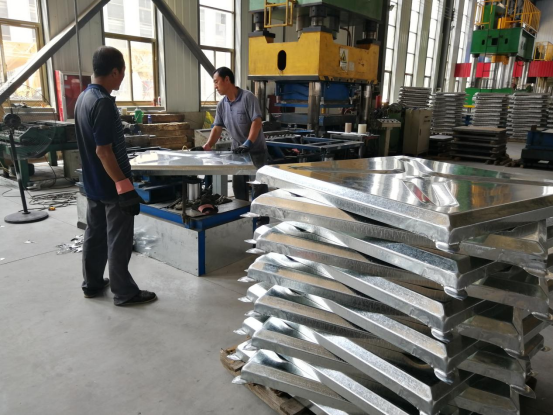

2. Modular Design Enhances Installation Efficiency

Weld-Free Assembly: All panels are bolted with non-toxic sealing strips, reducing the risk of leakage.

Flexible Configurations: Standardized panel sizes (1×1 m, 1×0.5 m, 0.5×0.5 m) allow custom tank dimensions and vertical installations up to 5 m.

Reduced Construction Time: A 200 m³ project can save up to 40% of labor hours compared to traditional welded tanks.

Transport-Friendly: Modular panels facilitate shipping to remote locations or tight urban sites.

3. Guaranteed Water Quality and Low Maintenance

Smooth interior surface reduces scale formation and inhibits bacterial growth.

Compliance with drinking water standards ensures safe potable water storage.

Maintenance savings: Regular flushing suffices; no frequent repairs or chemical treatments are required, reducing operational costs by ~30%.

4. Cost-Effective and Environmentally Friendly

Economical: 20–35% lower upfront cost than stainless steel tanks.

Eco-conscious: Made from 95% recyclable materials.

Energy-efficient: Optional insulation layers can reduce heat loss by 15%, making them suitable for solar thermal storage and hot water circulation systems.

5. Safe, Durable, and Reliable

Structural Reinforcement: Corrugated side panels and internal tie rods enhance pressure resistance and distribute load evenly.

Seismic Resistance: Design can achieve an earthquake rating of 8, providing reliable performance in earthquake-prone regions.

Pressure Capacity: Side panels withstand water pressures ≥0.6 MPa.

1. Material Technology: Triple Protection System

Protective Layer | Function | Process Requirement |

Zinc-Iron Alloy Layer | Active corrosion protection | Hot-dip galvanizing, zinc thickness ≥80 μm |

Pure Zinc Layer | Physical isolation | Dense, pore-free surface |

Passivation Layer | Anti-secondary oxidation | Chromate sealing treatment |

2. Structural Innovation: Pressure and Earthquake Resistance

Corrugated Panels: Increase load-bearing capacity and prevent deformation.

Multi-directional Tie Rods: Evenly distribute forces and enhance earthquake resistance.

3. Environmentally Friendly Process

Eco-friendly materials throughout production prevent zinc contamination of water and reduce environmental impact.

1. Capacity-Based Solutions

Small Systems (<50 tons): Ideal for residential communities and schools — single-layer cylindrical tanks.

Medium Systems (50–200 tons): Suitable for hospitals, hotels, and commercial buildings — modular rectangular tanks recommended.

Large Systems (>200 tons): Industrial and mining enterprises — require custom partitioned and reinforced tanks.

2. Industry-Specific Solutions

Fire Water Storage: Enhanced structural and pressure-bearing designs ensure uninterrupted emergency water supply.

Coastal High-Salt Areas: Thicker zinc layers combined with external epoxy coating for superior corrosion protection.

Low-Temperature Regions: Polyurethane foam insulation minimizes water temperature drop (<2°C over 24h at -25°C ambient).

Solar Coupled Systems: Tanks integrated with photovoltaic panels support energy self-sufficiency for monitoring and auxiliary systems.

Structural fit: Check site dimensions, floor load, and pipe layout.

Lifecycle cost: 10-year total cost is about 40% lower than stainless steel tanks, including equipment, installation, and maintenance.

Use a concrete foundation with U-steel support.

Inspect seals and bolts regularly.

Clean new tanks twice before use; use soft brushes for routine maintenance.

Avoid storing liquids above 70°C or corrosive chemicals.

Coastal or humid environments require more frequent inspection.