Spray nozzles play a vital role in the performance of industrial evaporative cooling towers. While often overlooked compared to other components like fans and fill media, the ability of nozzles to evenly distribute hot process water over the fill is a key factor that determines overall cooling efficiency, energy consumption, and system reliability. Selecting the right nozzles and maintaining them properly can significantly reduce operational costs and prolong equipment life across various industries.

This article delves into how spray nozzles affect heat transfer, the challenges caused by poor nozzle performance, essential design features of high-quality nozzles, and how to match nozzle types to specific tower configurations and water qualities. Practical maintenance recommendations are also discussed to help maximize system uptime and efficiency.

Effective evaporative cooling depends on maximizing the air-water contact area inside the tower. Spray nozzles atomize the incoming hot water into droplets and distribute them uniformly over the fill media, which increases the surface area for heat exchange.

Key factors affecting this process include:

Droplet size: Smaller droplets evaporate faster but risk being carried away by airflow (drift loss). Larger droplets reduce drift but may wet fill unevenly.

Spray coverage: Uniform water distribution is critical. Dry spots or oversaturated areas hinder heat transfer and can cause localized scaling or biological growth.

Spray pattern: Full cone nozzles produce dense coverage suited for crossflow towers, while hollow cone nozzles create fine droplets that improve heat transfer in counterflow towers.

A well-designed nozzle ensures stable spray geometry and efficient atomization, directly impacting thermal performance and energy use.

Spray nozzles operate in demanding conditions and can experience several issues that reduce cooling tower efficiency:

Clogging: Particulates, biological matter, and scale can block nozzle orifices, leading to uneven spray distribution.

Material wear: Exposure to chemicals, UV light, and temperature fluctuations can cause plastic nozzles to crack or metal nozzles to corrode, altering spray patterns.

Pressure mismatch: Nozzles not matched to system pressure may cause inefficient atomization or increased pumping energy.

Drift losses: Improper droplet size or worn nozzles can produce fine mist that escapes with airflow, increasing water consumption.

Addressing these issues starts with selecting nozzles designed for anti-clogging and chemical resistance, suitable for the operating environment.

High-quality nozzles combine design and material features to ensure reliable, efficient operation:

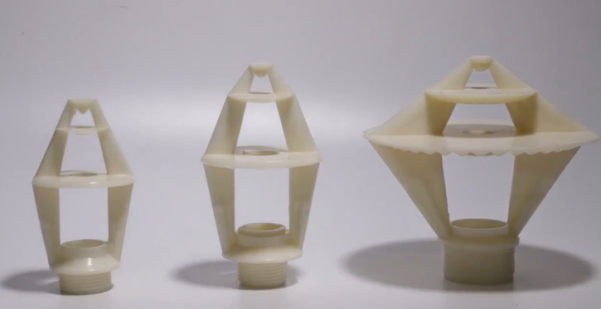

Spray pattern versatility: Full cone nozzles for wide coverage in crossflow towers; hollow cone nozzles for fine atomization in counterflow towers; spiral nozzles for anti-clogging performance.

Durable materials: Thermoplastics like ABS and polypropylene resist corrosion, scaling, and chemical attack. Stainless steel options are available for harsher conditions.

Anti-clogging design: Larger orifices, smooth internal surfaces, and self-cleaning geometries help maintain flow even with dirty water.

Low pressure drop: Optimized hydraulics reduce pump power requirements.

Ease of maintenance: Removable or tool-free nozzles simplify cleaning and replacement, reducing downtime.

Matching nozzles to tower design and site conditions is crucial:

Crossflow towers: Benefit from nozzles that produce larger droplets with wide spray angles to counter horizontal airflow effects.

Counterflow towers: Require nozzles that generate fine droplets vertically to maximize air contact time.

Water quality: Systems with suspended solids or hard water need clog-resistant nozzles such as spiral spray types.

Operating pressure: Nozzles must be compatible with pump pressure to maintain proper flow and spray characteristics.

Proper nozzle selection ensures uniform water distribution, optimal heat transfer, and reduced energy consumption.

Power generation: Stable, efficient cooling critical to turbine performance.

Petrochemical plants: Chemical-resistant nozzles reduce maintenance under harsh conditions.

Steel and foundries: Nozzles designed for high temperature and dirty water improve reliability.

HVAC and data centers: Low drift, quiet nozzles support critical thermal management and water conservation.

Regular upkeep keeps nozzles performing optimally:

Inspect nozzles every 3 to 6 months for damage or blockage.

Clean removable nozzles with non-abrasive tools to prevent mineral buildup.

Monitor system pressure for sudden drops indicating clogging.

Replace worn nozzles promptly to maintain consistent spray patterns.

Routine maintenance minimizes downtime and sustains cooling tower efficiency.

Spray nozzles are a small but essential component in industrial cooling towers that significantly influence thermal performance, water usage, and energy efficiency. Choosing nozzles designed for your tower type, water quality, and operating conditions, coupled with consistent maintenance, can yield measurable improvements in system stability and cost savings. Optimizing your cooling tower nozzles is a practical step towards enhancing the reliability and sustainability of your industrial cooling operations.

Contact us today to find the best cooling tower nozzle for your needs and improve your system’s efficiency.