Address

No.88, Qilian Street, High-Tech Zone, Shijiazhuang, Hebei 050000, China

Tel

+86 311 6779 0805

+86 188 4915 5666

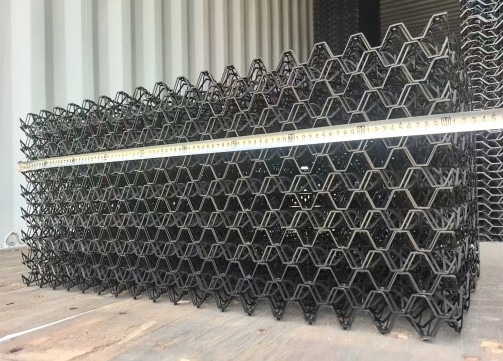

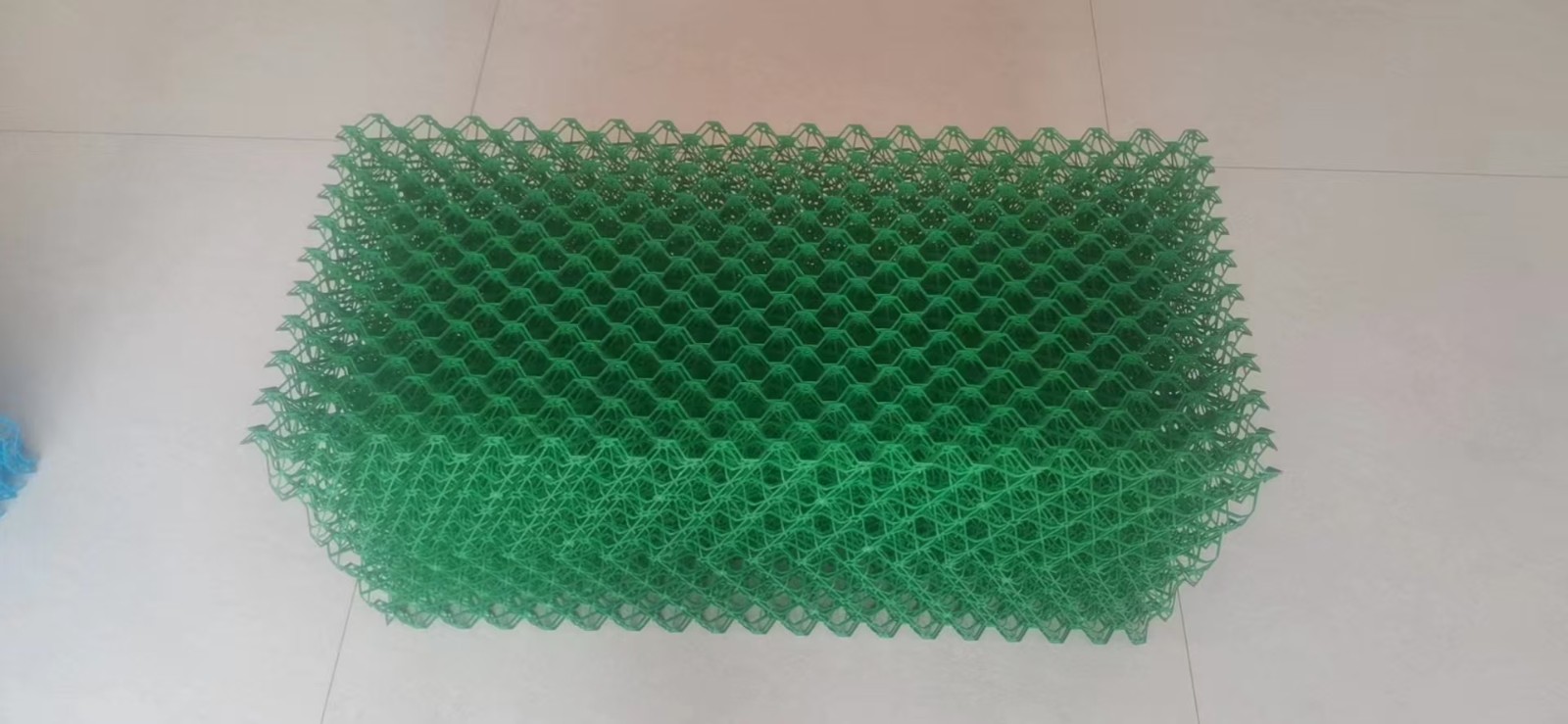

Trickle fills are a new type cooling tower fills that combines the features of splash fills and film fills. Its grid structure can effectively improve the water distribution effect and disperse the hot water sprayed by the nozzle, thus improving the heat transfer performance. For use in power, refining, chemical, steel, and food processing applications where water quality is poor. It is suitable for cooling waters with higher contents of suspended solids, oils and the like. The cooling fill can by walked upon without temporary boards or the like, it will not be eroded from the sprayed upon cooling water and it can be flushed with high pressure water jets.

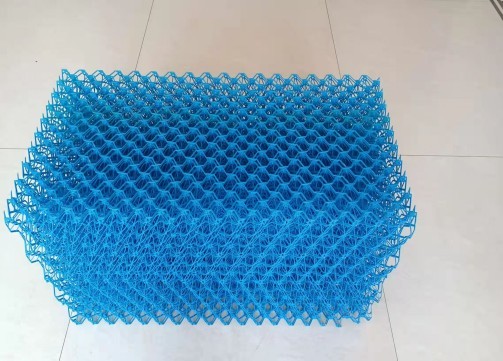

The mesh structure of the PP Net Fill is features high porosity, a large usable specific surface area, three-dimensional water flow, excellent mass transfer conditions, high air utilization, and is non-clogging, non-clumping, long-lasting, and easy to install.

It exhibits good overall performance and price-performance ratio in circulating water with poor quality.

Mesh packing material is particularly suitable for wastewater with poor water quality and high suspended solids concentration, as well as seawater environments.

Made of PP, it is injection molded, wedge-jointed into blocks, requiring no glue bonding, causing no pollution, and is more heat-resistant than PVC.

Power Plants: In power plants, cooling towers must efficiently handle high heat dissipation, often with poor-quality water containing suspended solids, oils, and other contaminants. Trickle Fill/PP Net Fill’s high porosity and non-clogging mesh structure allow it to effectively distribute water, even with high suspended solids. This ensures uniform water distribution across the packing, preventing blockages and optimizing heat exchange efficiency in environments where water quality may be less than ideal.

Chemical & Refining: Trickle Fill/PP Net Fill is essential for cooling systems in the chemical and refining industries, where water can be contaminated with chemicals, oils, and solids. Its corrosion-resistant and non-clogging properties make it highly durable and reliable in harsh chemical environments. The mesh structure ensures efficient water flow, even in high-contaminant conditions, helping maintain consistent cooling performance and reducing system downtime.

Food Processing: In the food processing industry, where both strict temperature control and water quality are paramount, Trickle Fill/PP Net Fill provides an ideal cooling solution. Its durable, non-clogging design ensures long-lasting performance, even with water that contains food particles or impurities. The high surface area of the mesh helps maintain consistent temperature control while minimizing the risk of clogging, which is critical in maintaining hygiene standards.

Steel Mills: Trickle Fill/PP Net Fill is well-suited for steel mills, where cooling towers operate under extreme temperatures and often process dirty water. The high-temperature resistance and durability of the material ensure that the cooling tower can effectively dissipate heat in high-heat environments while withstanding exposure to contaminants like dust, oils, and metals. The mesh structure improves water distribution and airflow, maintaining optimal cooling efficiency even under challenging conditions.

In cooling tower operation, the mesh packing system allows circulating water to be evenly sprayed from the nozzles onto the packing layer below via the distribution pipes. The three-dimensional perforated ribs effectively disperse the water droplets, breaking large water droplets into smaller ones, resulting in a more uniform distribution of circulating water across the next layer of packing. This process ensures three-dimensional water flow, excellent mass transfer, high air utilization, and prevents wastewater blockage and clumping. The PP material is high-temperature and corrosion-resistant, avoiding the gaps and uneven water distribution that can occur at the interface between nozzles when water volume is insufficient, as is common with conventional membrane packing. This allows for full utilization of the membrane packing's heat exchange area, enhancing heat exchange performance. Simultaneously, the mesh packing's low ventilation resistance further increases airflow, improves heat exchange efficiency, and optimizes the overall thermal performance of the tower.

| Item No. | Item Name | Unit | Indicator | |

| 1 | Material | Modified PP (Anti-aging) | ||

| 2 | Structure | Mesh Structure | ||

| 3 | Specific Surface Area | m2/m3 | >125 | |

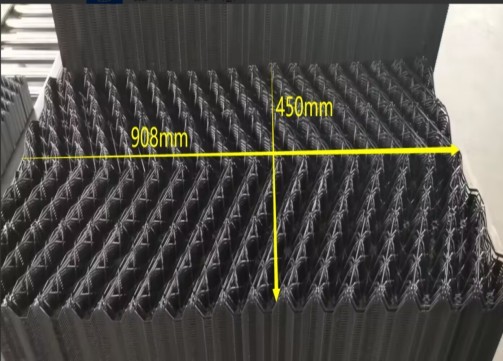

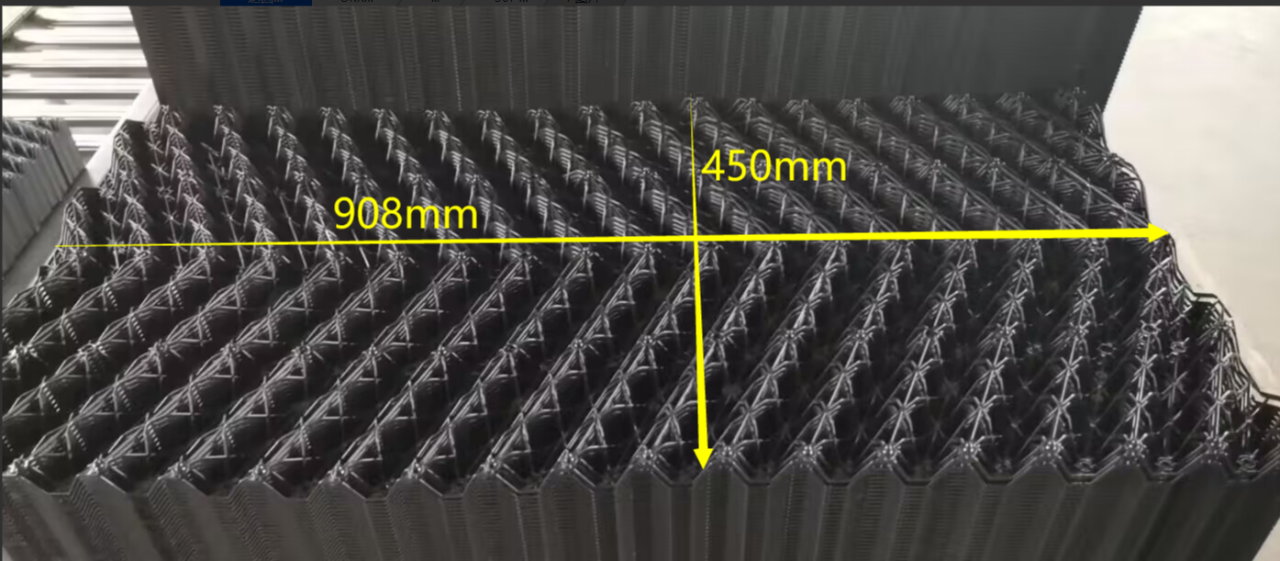

| 4 | Single Sheet Size | Length | mm | 908 |

| Width | 450 | |||

| Wave Height | 20 | |||

| 5 | Maximum Application Temperature | ℃ | 80 | |

| 6 | Porosity Ratio | % | ≥95.8 | |

| 7 | Assembly Method | Wedge Joint | ||

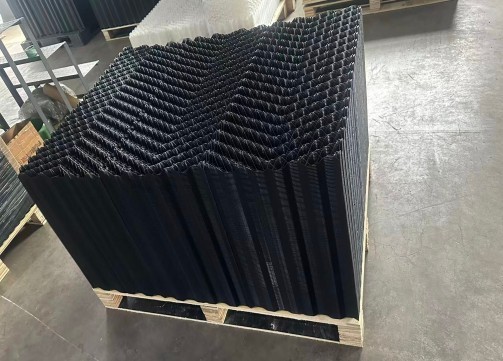

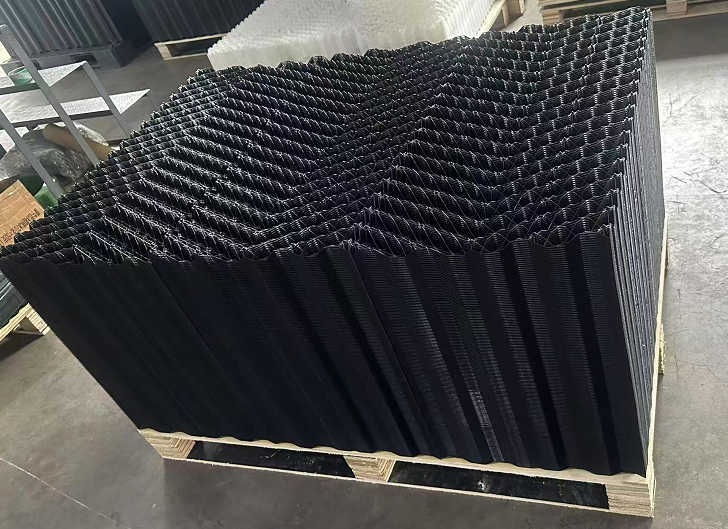

1.Remove the stretch film and four corner protectors from the tray's mesh packing

2.Assemble on a hardened, level surface. Take a stack of mesh filler from the tray and begin assembling it piece by piece.

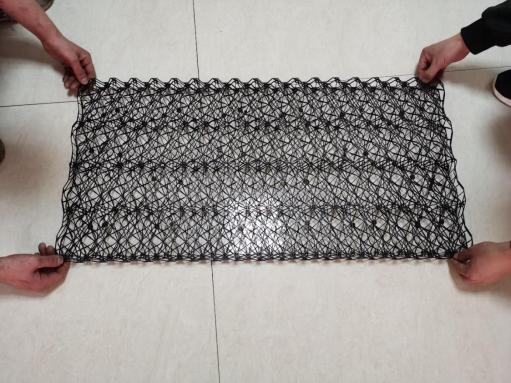

3.To ensure efficiency, two workers are required when assembling the mesh packing. First, place one sheet of packing material on a hardened, flat surface as the assembly base, ensuring the interlocking joints are facing upwards, as shown in the right diagram.

Then, place another sheet of packing material on top of the base packing material. This sheet should be placed in the opposite direction along its length to the sheet below. Each sheet of packing material has 72 interlocking joints; ensure that the interlocking joints of the lower packing material are aligned with the interlocking holes of the upper packing material.

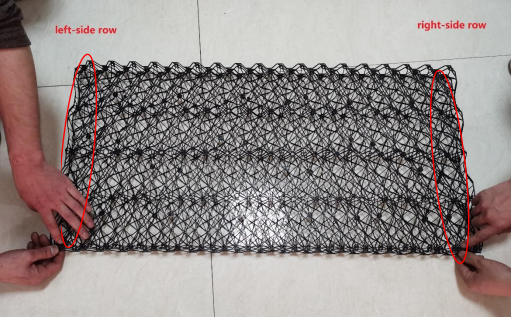

4.There are five interlocking points on the far left and far right of the mesh packing. Two workers assemble it simultaneously, ensuring that the five interlocking points on the far left and the five interlocking points on the far right are tightly interlocked together.

5.Then grasp the middle of the upper mesh packing and lift it upwards to eight to ten centimeters, then release it naturally. This action ensures that all the fittings of the lower packing are aligned with all the fitting holes of the upper packing.

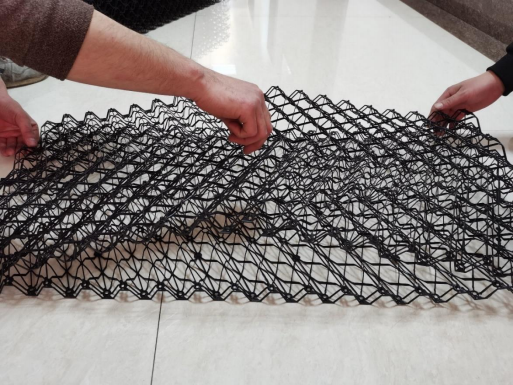

6.Then press the middle position to ensure that the hole in the middle of the upper mesh packing is tightly connected to the lower packing insert.

7.Then repeat steps 3 to 6, assembling one piece at a time until all 20 mesh filler pieces are assembled.

8.Place a flat solid wood board measuring 1000mm long x 500mm wide x 20mm thick on top of the filler block.

9.The worker stands on the wooden board and applies even pressure to the board until all the joints and holes of the filler block are tightly connected.

10.At this point, a standard mesh packing block is assembled. It is essential to ensure that over 95% of the mating points are tightly connected.

What is the maximum temperature that Trickle Fill/PP Net Fill can handle?

Trickle Fill can operate effectively at temperatures up to 80°C.

How do I install Trickle Fill/PP Net Fill in my cooling tower?

Installation is straightforward with the wedge-jointed design, requiring no glue bonding or temporary boards.

How do I maintain Trickle Fill/PP Net Fill?

The material is easy to clean with high-pressure water jets, and its non-clogging nature reduces maintenance frequency.

Can Trickle Fill/PP Net Fill be used in seawater cooling towers?

Yes, it is ideal for use in environments with high suspended solids, including seawater.

For more intuitive installation instructions, please see the trickle fill assembly video. Please feel free to contact us! sales@coolingtowerinfill.com