Address

No.88, Qilian Street, High-Tech Zone, Shijiazhuang, Hebei 050000, China

Tel

+86 311 6779 0805

+86 188 4915 5666

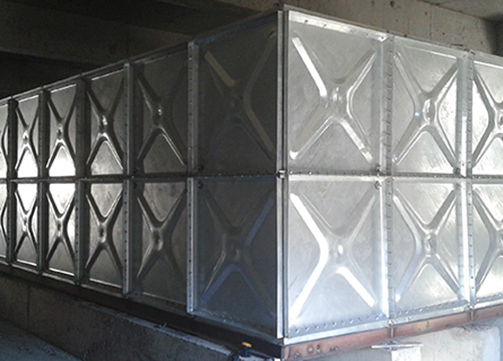

Galvanized steel water tank

The hot dipped galvanized steel water tank is defers to the manufactured new type water tank.The manufacture and the installmentof tank have no influence of the construction.There are not needed the welding apparatus, the surface is hot dipped galvanize antiseptic treatment. It’s artistic durable, prevents two times pollution to water quality and it beneficial to human health.

The water tank meets the construction product standardization, the seriation and the factorization request.

This product is suitable for the construction water storing,the regulating tank,heating system's inflation water tank,the condensate tank as well as the building construction, the geological prospecting,the industry, the defense project and so on temporarily store water tank.This water tank volume has 24 kinds specifications, select for the design. The engineer also can design according to the water tank's length, width, high then factory assembles.

The inlet pipe, the outlet pipe, the overflow caliber and the position of water tank is depends on the designing. All around the water tank should have no less than 700mm channels, the bottom and the cover should no less than 600mm. When it installed, the bottom and all around between the bottom standard plate's joins must be located on the support. Click Here and our expert will answer all your questions!

For the steel panel water tank series,there are three kinds of water tank:

1.Hot dip galvanized steel water tank

Carbon steel panel immersed in molten zinc solution to get Fe Zn alloy.Anti-corrosion from kinds of liquid.

2.Enameled steel water tank

Enameled steel plate surface to prevent the steel plate from rust .One layer black outside,double layers white inside.It can store drinking water .

3.Gush-paint steel water tank

In electrostatic interaction ,the powder absorbed in the panel surfact.Then through high temperature baking flow get finnal coationg effect.

Water Tank Height(mm) | Thickness of each panel(mm) | ||||||

| Bottom | 1st side | 2nd side | 3rd side | 4th side | 5th side | Top | |

| 1000 | 3 | 3 | / | / | / | / | 2 |

| 1500 | 3 | 3 | 3 | / | / | / | 2 |

| 2000 | 3 | 3 | 3 | / | / | / | 2 |

| 2500 | 4 | 4 | 3 | 3 | / | / | 2 |

| 3000 | 4 | 4 | 3 | 3 | / | / | 2 |

| 3500 | 4 | 4 | 3 | 3 | 3 | / | 2 |

| 4000 | 5 | 5 | 4 | 3 | 3 | / | 2 |

| 4500 | 5 | 5 | 5 | 4 | 4 | 3 | 2 |

| 5000 | 5 | 5 | 5 | 4 | 4 | 3 | 2 |

Brief Introduction:

1.Raw material: carbon steel

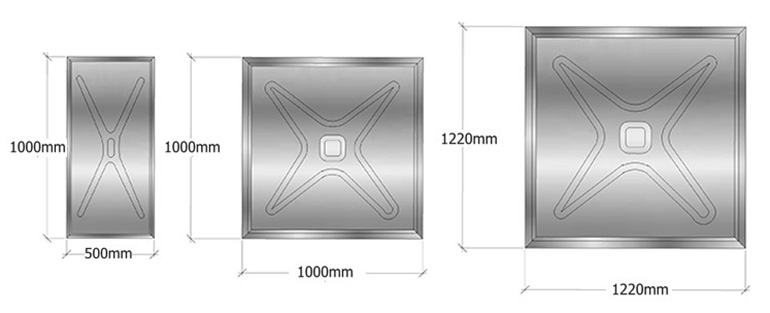

2.Panel size: 1.22*1.22m,1*1m, 1*0.5m, 0.5*0.5m

3.Process technique: ramming craft

4.Connection way: bolted

5.Panel thickness(according to height):2-6mm,it based on the different height of water tank

6.Foundation: Concrete foundation and U-steel bottom base

7.Wide application: as the storage equipment for drinking water, reclaimed water and fire water,water tank has widely used in mining, residential buildings, hotels, office buildings, schools, restaurants and other public facilities.

8.Water tank's thermal insulation: all kinds of water tank can were the thermal insulation coat to deal with temperatu-re extremes.

9.Tank of different height use different bottom ,side and top panel strictly according to the assemble principle.

10.The assemble principle guarantee safety confficient by reasonable saving of materials.It can serve more than 50 years.

STEP-BY-STEP Assemble:

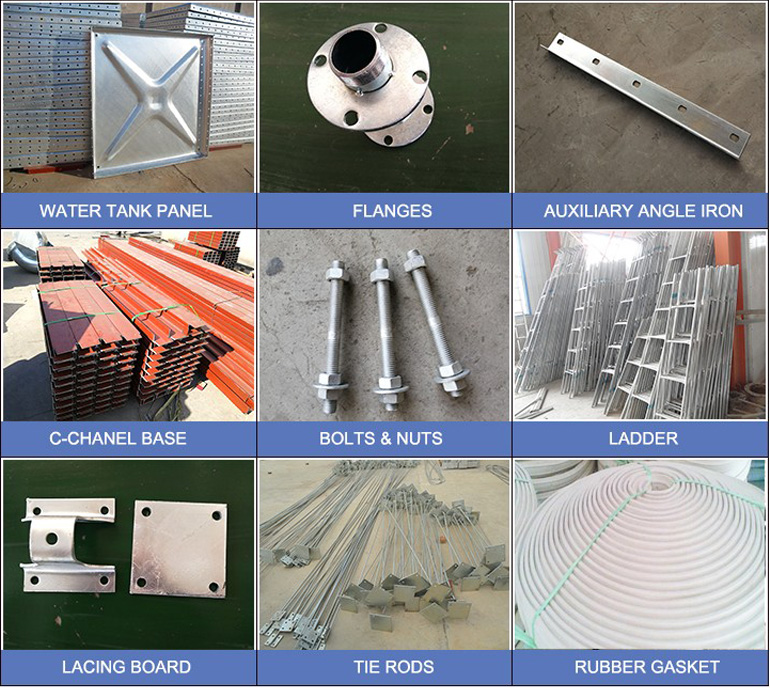

Step 1. Install steel footings on leveld concrete foundations.

Step 2. Align galvanized steel panel to be pre-assembled.

Step 3. Place rubber sealant from ready-to-use roll between panels.

Step 4. Conect panels with bolts and nuts.

Step 5. Position bottom panel sections,and finish up base of tank .

Step 6. Position three sides of the tank .

Step 7: Position and fix roof panels and if required ,roof support pipes and plates.

Step 8: Install reinforcement if required.

Step 9: Close up the tank with the fourth side .

Step 10.Finish the internal or external reinforcement .

Step 11.fill and test .

Cautions:

1. Please do not store water higher than 70°C or other liquid (chemicals, oil and so on).

2. Water tank must keep away from fire.

3. Prevent pollutants and plunges from outside.

4. Use soft apparatus to clean. As to the new water tank, clean twice before use

| Feature | National Standard (GB) | British Standard (BS EN) |

|---|---|---|

| Steel Grade | Q235B or equivalent carbon steel plates | BS EN 10346 galvanized steel, DX51D+Z275 (or equivalent) |

| Galvanizing Thickness | 86–275 g/m² depending on corrosion class | Minimum 275 g/m²; uniform coating verified by BS EN ISO 1461 |

| Surface Treatment | Hot-dip galvanized, smooth, defect-free | Hot-dip galvanized with uniform coating; passivation recommended |

| Panel Assembly | Bolt-together panels with rubber gaskets or spot welding | Mechanical or welded joints meeting leak-proof criteria; sealants per BS EN 12266 |

| Structural Design | Panels designed per GB50015 for standard water pressure loads | Panels designed per BS EN 1993-1-1 (Eurocode 3) for pressure, wind, and seismic loads |

| Potable Water Compliance | GB 5749 / GB 50015 for drinking water safety | BS 6920:2014 – materials in contact with drinking water must not affect quality |

| Interior Coating | Optional food-grade epoxy | Food-grade epoxy or PE lining required for potable water storage |

| Leak & Pressure Testing | Hydrostatic test per GB50015 | Hydrostatic and pressure testing per BS EN 12266 |

| Dimensional & Strength Verification | Panel thickness, weld quality, tie rods checked per GB | Mechanical properties and structural calculations verified per BS EN 10346 and BS EN 1993 |

| Installation Requirements | On-site bolt assembly; foundation per GB50009 | On-site assembly or prefabricated units; comply with BS EN 1991 for loads and site safety |

| Maintenance Guidance | Periodic inspection of zinc coating and gaskets | Regular inspection per BS EN recommendations for potable water systems |