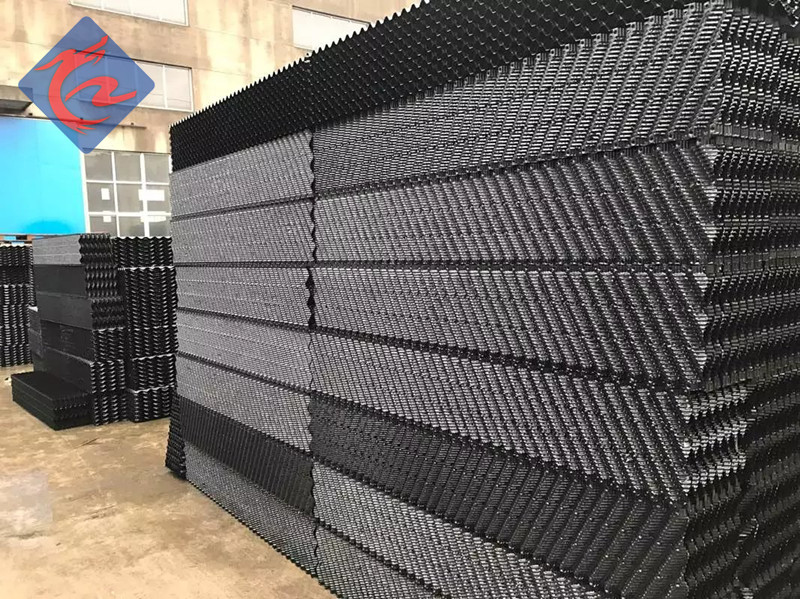

Cooling tower fill comes in multiple different styles that have different efficiency levels, pros and cons. The cross-corrugated fill that is used in many cooling towers can be extremely efficient because it offers the most surface area possible, exposing the most water to the most air possible, but because of this design, it’s easy for contamination to take place. This is often called “fouling” and cross-corrugated fill is known for being susceptible to fouling.

Vertical offset fill is a little more resistant to the permeation of outside pollutants, but offers a still fairly efficient environment in which the water can circulate, being exposed to a reasonable cooling process. The efficiency of the cross-corrugated platform is definitely reduced in the vertical offset fill design, but it can be an effective trade off of the small loss of efficiency for increased long term life and uptime, because of reduced contamination.

The vertical fill model is perhaps the least efficient cooling mechanism overall, but when water enters a system dirty and requires cooling, it is really the best solution. The condition of the water entering the system is a primary evaluation criteria when selecting the right kind of film fill for a cooling tower. Vertical fill offers a very low rate of contamination, and very limited pressure drop as the water makes its way through the system.

Learn more cooling tower infill, you can via www.coolingtowerinfill.com.