Address

No.88, Qilian Street, High-Tech Zone, Shijiazhuang, Hebei 050000, China

Tel

+86 311 6779 0805

+86 188 4915 5666

GRP water tanks is the abbreviation of Fiberglass Reinforced Plastic water tanks,are leading industry and civil standard water storage equipment on the market.There are many advantages such as lightweight,strong structure,modular and sectional assembly by standard panels design. GRP tanks provide safe environment with no risk of bacteria corrosion.Due to the raw material to manufacturing water tank is self-resistant to bad weather and high temperature,meaning the water tank lifespan is long.Meanwhile,all raw materials attribution decides the water tank is pliable,application wide for any specific access or needs.

One of the most common uses of GRP tanks is in wastewater treatment plants (WWTPs). Their resistance to corrosion and chemical degradation makes them perfect for storing activated sludge, aeration liquids, or treated effluents.

GRP tanks can be designed as cylindrical vertical units or rectangular modular panels, providing flexibility for space constraints and capacity requirements.

In industries dealing with chemicals, process fluids, and oils, storage safety and reliability are critical. GRP tanks are ideal for these environments due to their ability to resist acidic or alkaline solutions.

They are often installed in refineries, chemical plants, and food processing facilities, where exposure to aggressive liquids can quickly degrade steel or concrete tanks.

Sustainability is another advantage of GRP tanks. The long life span and low maintenance requirements reduce waste and energy consumption over time. Many GRP tanks are also fully recyclable at the end of their service life, minimizing environmental impact.

Moreover, their light weight reduces transport emissions during delivery and installation, contributing to eco-friendly industrial operations.

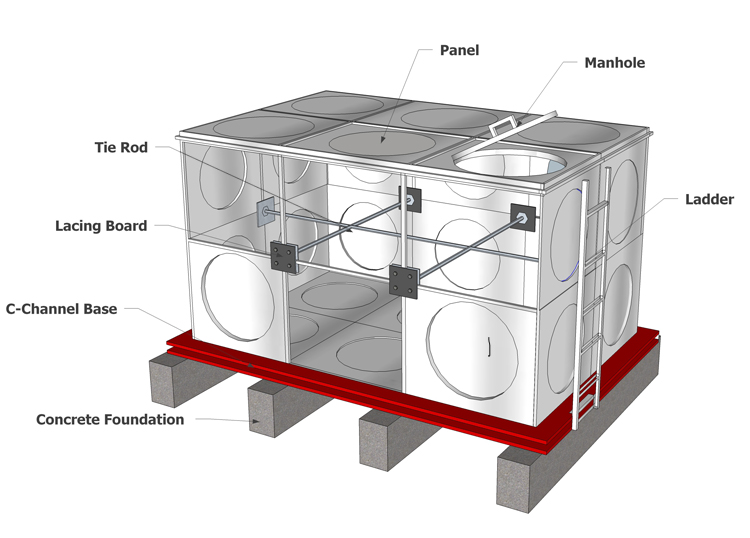

GRP module water tank is a new type water tank after the development of reinforced concrete water tank , steel plate water tank, stainless steel water tank.GRP water tank combined with the GRPmolding panel, sealing materials, metal structure and piping system to onsite assemble together.

Cleanliness and saniation

SMC Water Tanks satisfy relevant Food Sanitation standards. Since exterior light is completely blocked, bacteria generation and germ growths are prevented. In particular, when large panels are employed, existing water tank interior structures are eliminated, allowing long-term sanitary use of water tanks.

Excellent durability

The interior structural components of a water tank consist of Storage Tank System (STS) and Base Layer (STS PE coating and Winding Pipes) that prevent corrosion or rusting.

The external components are Melt Zinc plated, thus having semi-permanent useful life.

Complete water tightness

Special sealants with international patents are used to guarantee water tightness.

Rational capacity design

Various panel designs are used to design tanks of all capacities and dimensions.

Convenient installation

Standardized parts are used for on-site installation so that materials can be brought into restricted areas for convenient installation.

Excellent thermal protection

Single panels are used for water tanks installed underground, while the insulated panels, which are single panel with insulation material compressed together, provide excellent insulation on water tanks installed outdoors.

1) Strong resistance to corrosion.

2) Reasonable structure design.

3) All welded on-site combination. High strength, good sealing, prevent secondary pollution of water quality.

4) Light weight, that is one half of ordinary steel plate water tank.

5) Easy to install.

6) Clean, bright, beautiful appearance.

Water tank size: Can be made as your reuqest.

Panel size: 1mx1m, 0.5mx0.5m, 1mx0.5m

Wall board thickness: 5mm,8mm,10mm,12mm,14mm,16mm etc.

DESIGN PARAMETERS FOR SECTIONAL TANK | ||

Tensile Strength | ≥70MPa | |

Flexural Strength | ≥100MPa | |

bending modulus | ≥7.0GPa | |

Barcol Hardness | ≥60MPa | |

Water Absorption | ≤1.0% | |

Fiberglass content | ≥25 25% | |

Light transmission | Nil | |

Outdoor weathering(Natural sunlight) | Stabilized | |

Toxicity | Nil | |

Micro biological growth | Nil | |

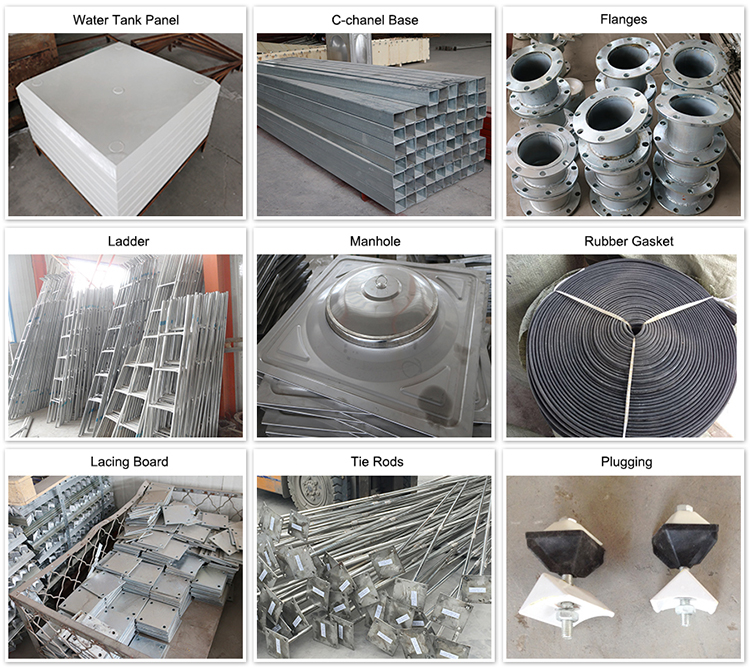

1) Support for Panels: The panels shall be supported externally or internally by an adequate support system. External Reinforcement - Hot Dipped Galvanized Steel Internal Reinforcement - Hot Dipped Galvanized or Stainless Steel 304 rod support and tie-rod

2) Sealing Materials: Non toxic Rubber foam to be used for all jointing, it is especially developed with long experience and technology on GRP products. It maintains soft itself and adhesives even at low temperatures

3) Bolts, nuts and washers for the assembly of panels: Exposed externally are hot dipped galvanized steel and in contact with water internally are hot dipped galvanized steel or stainless steel 304

4) Flange: the flanges for inlet, outlet, drainage, overflow are hot dipped galvanized steel or stainless steel 304

5) Ladders: GRP sectional tank of 1.5m depth or more shall be provided with internal ladder made up of materials same with the supports. The external ladders shall be galvanized mild steel or equivalent

6) Drainage: The dome shaped bottom panel with a concave drain panel facilitates complete and fast drainage. The concave drain panel has been designed to ensure the periodic cleaning and inspection of tank

7) Overflow Screens: it can be supplied with a screen overflow having a micro mesh filter

8) Man-hole opening & Inspection Hatches: the size can be customized; normally it is supplied with a standard size of: 600 x 600mm. the opening can be designs of bolt, seal-tight locking arrangement

9) ABS roof vent with PE insect screen

10) Float level indicator, optional SS304 for internal and external support structure are available on request.

All panels can be lifted by hand, with no special equipment required even where access is difficult, and installation can progress quickly and efficiently.

Step 1. Install steel footings on leveled concrete foundations.

Step 2. Align galvanized steel panels to be pre-assembled.

Step 3. Place rubber sealant from ready-to-use roll between panels.

Step 4. Connect panels with bolts and nuts.

Step 5. Position bottom panel sections, and finish up base of tank.

Step 6. Position three sides of the tank.

Step 7. Position and fix roof panels and if required, roof support pipes and plates.

Step 8. Install reinforcement if required.

Step 9. Close up the tank with the fourth side.

Step 10. Finish the internal or external reinforcement.

Step 11. Fill and test.

The manufacturing process of GRP tanks involves molding or panel assembly, depending on the required size and application.

Resin Preparation: A resin system (usually polyester, vinyl ester, or epoxy) is selected based on the desired chemical resistance.

Fiber Reinforcement: Fine glass fibers are layered into the resin, creating a solid yet lightweight structure.

Molding or Panel Fabrication: The mixture is shaped through hand lay-up, filament winding, or compression molding. Large tanks are often made from modular panels bolted together on site.

Curing and Finishing: The tank is left to cure, after which it is trimmed, tested, and finished with UV-resistant coatings.

This process ensures each GRP tank is robust, leak-proof, and designed for decades of use — even in harsh industrial environments.